In the sophisticated realm of contemporary industry, the intricate role of aluminum in vacuum chambers and semiconductors is important to address. Overlooking this would sidestep an integral chapter of technological advancement where aluminum aptly addresses the exacting requirements of the semiconductor industry.

Upon closer examination, the interrelationship between vacuum chambers and semiconductors becomes evident. Semiconductors necessitate the pristine environment of a vacuum or the presence of inert gases during their development and evaluation phases. Aluminum, given its multifaceted strengths, has become pivotal in catering to the unique needs of this sector.

Let’s delve deeper into the role of aluminum in the nuanced domain of vacuum chambers and semiconductors.

A Controlled Environment

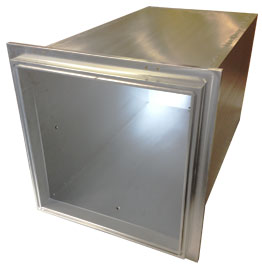

Essentially, a vacuum chamber represents a controlled void, devoid of air and associated gases, fostering scientific activities that replicate the void of outer space. These chambers are adaptable, facilitating specific gases for designated roles, serving pivotal functions ranging from vacuum drying to advanced coating processes.

Various materials, including ceramics, glass, stainless steel and notably aluminum, are employed to craft these chambers. Aluminum, given its optimal blend of strength and weight, often becomes the preferred choice. The assembly of these chambers epitomizes precision engineering, with every component meticulously designed to preserve the vacuum environment.

The Aluminum Epoch in Vacuum Applications

Aluminum showcases formidable strength, effectively countering vacuum pressures. Its inherent corrosion resistance ensures its durability in demanding settings. Furthermore, aluminum possesses unique attributes such as minimal hydrogen permeation, protection against carbon contamination, and a natural oxide barrier ensuring purity. It also synergizes well with processes like anodization, yielding advantages that are renowned in industry circles.

Semiconductors: The Digital Era’s Pulse

The semiconductor domain represents a complex interplay of electronic activities. These components, which strike a balance between conductors and insulators, have been instrumental in driving the digital revolution. Their nuanced manipulation symbolizes the essence of our digital transformation.

Aluminum: The Linchpin in Semiconductor Fabrication

In the realm of semiconductors, aluminum stands out prominently. Its compatibility with silicon dioxide, fundamental to semiconductors, is unmatched. Aluminum’s electrical properties make it invaluable in the intricate process of microchip manufacturing. Even as metals like copper and silver present their attributes, aluminum continues to be the reliable ally, ensuring optimal performance without compromising on efficiency.

Aluminum’s prowess is evident in sputtering technology, facilitating the deposition of ultra-pure materials. Within these chambers, intricate circuitry designs materialize, setting the stage for the semiconductor’s function. Specifically, the aluminum alloy 6061, when anodized, offers superior resistance to corrosion, ensuring the impeccable functioning and longevity of semiconductor devices.

At this convergence of aluminum, vacuum chambers, and semiconductors, lies a testament to innovation and progress, underscoring aluminum’s pivotal role in addressing the demands of the current era.

Advantages of Aluminum in Vacuum Chambers

- Strength-to-Weight Ratio: Aluminum’s impressive strength, despite its lightness, makes it ideal for applications necessitating resilience and ease of handling.

- Alloy Flexibility: Beyond its elemental form, alloys such as 6061 amalgamate the benefits of constituent metals, catering to specialized requirements.

- Inherent Oxide Barrier: Aluminum’s naturally occurring oxide layer serves as a defense against corrosion and oxidation.

- Thermal Conductivity: Its superior thermal conductivity ensures consistent temperature regulation, mitigating potential hotspots.

- Economic Viability: Its enduring performance provides long-term value.

- Corrosion Resistance: Dispelling misconceptions, aluminum’s oxide layer offers commendable corrosion resistance, outperforming several metals.

- Temperature Stability: Aluminum retains its properties across extensive temperature ranges, apt for diverse settings including the stringent conditions of vacuum chambers.

- Operational Ease: Combining lightness with robustness, aluminum is conducive for intricate applications, particularly in vacuum chambers.

GNB Corporation stands as a premier producer of vacuum equipment, encompassing vacuum chambers, valves, and related components. Holding ISO-9000 and ASME U-stamp credentials, GNB dominates the market with its advanced vacuum solutions. We cater to a diverse range of sectors, including semiconductor production, scientific research, furnace operations, pressure container systems, space ventures, medical equipment, cancer therapy, vacuum layering techniques, flat screen technology, direct production processes, solar module fabrication, and metal treatment.

To learn more about our products, click here.