Cryo-coils and other products

Products

- Cryo-coils: Cryogenic coils used to increase pump speed in a vacuum chamber

- Diffusers: Baffle used to deflect the movement of gasses

- Heat Shields: Heat load protection for cryopumps and other components

- Engineering: Conductance and technical data for baffles

Cryo-coils are used to rapidly reduce the pressure inside a vacuum system. They use the same principle as a cryo-pump: they create a vacuum by freezing the water and other molecules. Another name for a cryo-coil is Meissner coil. Cryo-coils provide one of the fastest vacuum pumping methods because just as fast as a surface inside a vacuum chamber can be made cold, the vacuum pressure can be reduced.

Water vapor is 65% to 95% of the gas load in most vacuum systems. A cryo- coil freezes the water vapor and can reduce the pump-down time by 25% to 75%. The following chart on page 23 of the catalog on the left shows the water vapor partial pressure according to temperature. The colder the cryo-coil the lower the expected vacuum pressure.

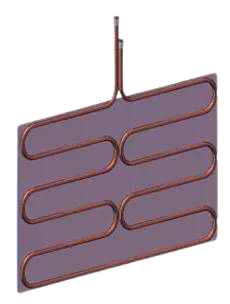

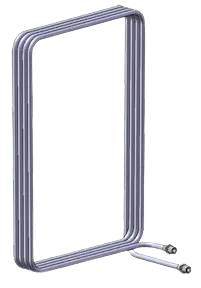

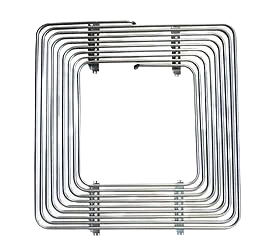

Cryo-coils consist of a tube which is used to flow a cold liquid or gas and a large surface area. Often the coil is brazed to a shroud or backing plate. Other times fins are attached to the coils.

The lower the temperature the lower the water vapor pressure. For example, to reach a pressure of 1×10-2Torr, the average cryo-surface temperature needed is -96°F(-71°C). Whereas, to reach a pressure of 1×10-7Torr, an average cryo-surface termperature of -201°F(130°C) is needed.