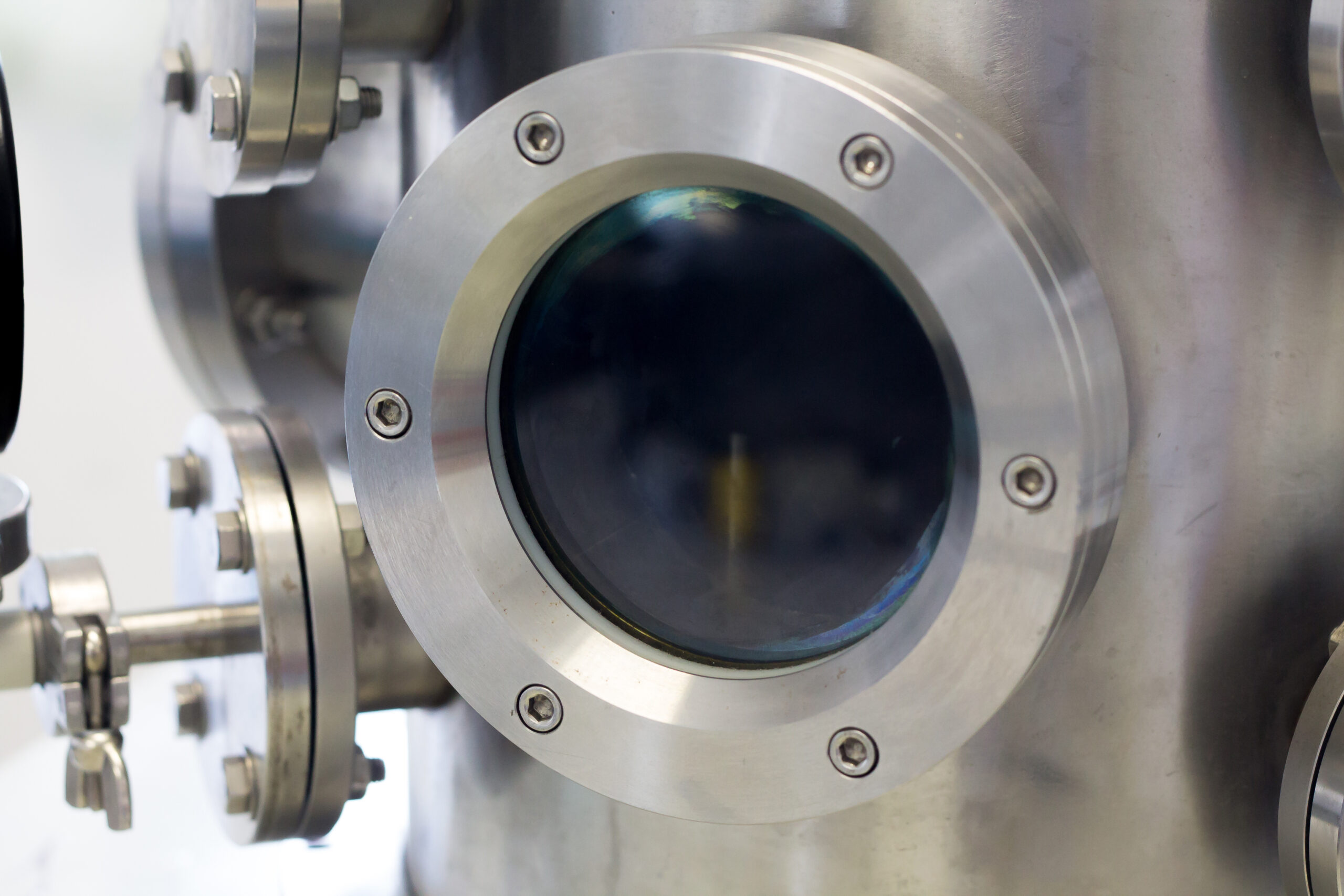

Vacuum chambers are versatile tools used by many industries for many different purposes. They create an airless environment for research and experimentation and to provide an environment that is void of contamination.

By removing all air from the chamber, researchers can study reactions at extremely low pressures or test new materials in a completely oxygen-free atmosphere. Many processes such as electron beam, proton beams, neutron beams and high-powered lasers are disturbed by air, and therefore a vacuum is required. Vacuum chambers are excellent thermal insulators and allow scientists to conduct experiments at temperatures far below those found in nature, allowing them to observe the behavior of particles under extreme conditions. Also, vacuum chambers are used to simulate the conditions of special environments such as outer space.

Another use of a vacuum chamber is to create a sterile environment. This is necessary in filling syringes, storing lab samples over long periods of time without degradation, and the lyophilization (freeze drying) of food. Samples such as biological specimens, organic matter and other delicate substances need a completely sealed environment with no exposure to oxygen or contaminates in order to remain viable over time. Such an environment is only attainable through the use and operation of a vacuum chamber.

Additionally, vacuum chambers are essential tools for the creation and manufacturing of intricate components like titanium metal, super conducting motors or semiconductors, which require exacting standards in order to function correctly. By using a pressure differential between two compartments inside the chamber — one side filled with air, the other evacuated — technicians can use glove boxes to carefully align small components with great accuracy while reducing the risk of damage due to physical contact or heat transfer.

But why stainless steel? Let’s take a look at five reasons why you should use stainless steel for a high vacuum in chamber.

Durability

Due to its strength, stainless steel can withstand extreme temperatures, pressures and corrosive environments without deformation or damage. This makes it ideal for use in vacuum chambers where precise temperature control is required. It has high strength making it suitable for use in cryogenic systems and its excellent corrosion resistance makes it ideal for efficient cooling processes.

In addition, due to its non-reactive properties with certain chemicals, it is often the material of choice when working with hazardous materials. This makes it ideal for laboratory equipment where contamination could occur if not adequately protected from the environment.

Its ability to withstand extreme temperatures, pressures and corrosive environments without deformation or damage make it an invaluable asset in many engineering applications that require highly specialized materials that are both durable and cost-effective.

Non-Magnetic Properties

Now, let’s take a look at the non-magnetic properties of stainless steel and how it is ideal for applications where magnetic fields are a concern.

The most common type of stainless steel for vacuum chambers is “type 304L,” which is an incredibly strong material that is also resistant to corrosion and heat, as is, making it a popular choice for many engineering applications. One key feature of stainless steel is its non-magnetic properties. Most ferromagnetic materials become magnetized when exposed to external magnetic fields, but this is not the case with stainless steel. This makes it ideal for applications where magnetic interference could be an issue, such as producing accurate measurements with sensitive instruments. Additionally, some medical implants also require non-magnetic materials in order to avoid interference from scanners or other diagnostic devices.

Stainless steel’s non-magnetic properties can also be beneficial in other industries like computer technology. Hard drives are typically made using ferromagnetic materials, which can cause interference with other electrical components on the motherboard, whereas stainless steel does not generate any magnetic field on its own and therefore, does not interfere with other devices.

So, stainless steel’s non-magnetic properties make it extremely versatile and suitable for a wide range of applications requiring precision measurements or minimal interference from external sources such as MRI scans or computer components.

Cost Efficiency

Stainless steel is typically less expensive than other materials like titanium or some aluminum alloys and it can last much longer with minimal maintenance. This makes it an attractive option for many industries because they can achieve quality results without having to spend too much on expensive materials. Additionally, the durability of stainless steel helps to reduce maintenance costs over its lifetime since it does not require frequent replacement due to damage. Unlike aluminum, which can deform when sealing against soft copper gaskets, stainless is more durable and is the common sealing material for use with CF gaskets.

Low Outgassing Rates

In order to achieve a higher vacuum level the chamber must be built from a clean material with low permeability and a low outgassing rate. Outgassing occurs when water vapor, air or other gasses leave the surface of a material after the air has been evacuated from within the chamber. These gas molecules add to the small amount of remaining air in the chamber and thus increase the pressure. Stainless steel does not hold onto gas molecules as tightly as carbon steel, plastics ceramics and many other materials. Therefore, it has a low outgassing rate and is an excellent material for vacuum chambers.

Easy To Clean And Sanitize

Stainless steel an ideal choice for anyone looking for a chamber that is easy to clean and sanitize. Since it is nonporous and resistant to corrosion, it can be easily wiped down with a damp cloth and a suitable disinfectant to ensure maximum cleanliness and hygiene.

Additionally, because stainless steel does not absorb any liquids it is also possible to use steam cleaning techniques without causing damage or discoloration of the material itself.

Where To Buy A Stainless Steel Vacuum Chamber

GNB is highly skilled at manufacturing vacuum chambers from aluminum, steel, stainless steel and other materials, but one of the most common materials is stainless steel. These vacuum chambers are designed to meet the needs of various industrial and scientific applications. Our state-of-the-art manufacturing processes ensure that our chambers are made with only the highest-grade type 304L stainless steel for superior strength and heat resistance compared to other materials.

Choosing a stainless steel vacuum chamber from GNB guarantees you quality results while also being more cost-effective. It is our goal that after every customer works with us, they say, “Wow!” We are confident you will too, no matter the vacuum model you purchase from us. Also, make sure you ask us about our custom vacuum chamber options.

So, if you are looking for a top-notch seller of high vacuum stainless steel chambers, contact us today.