When you might need custom vacuum chambers

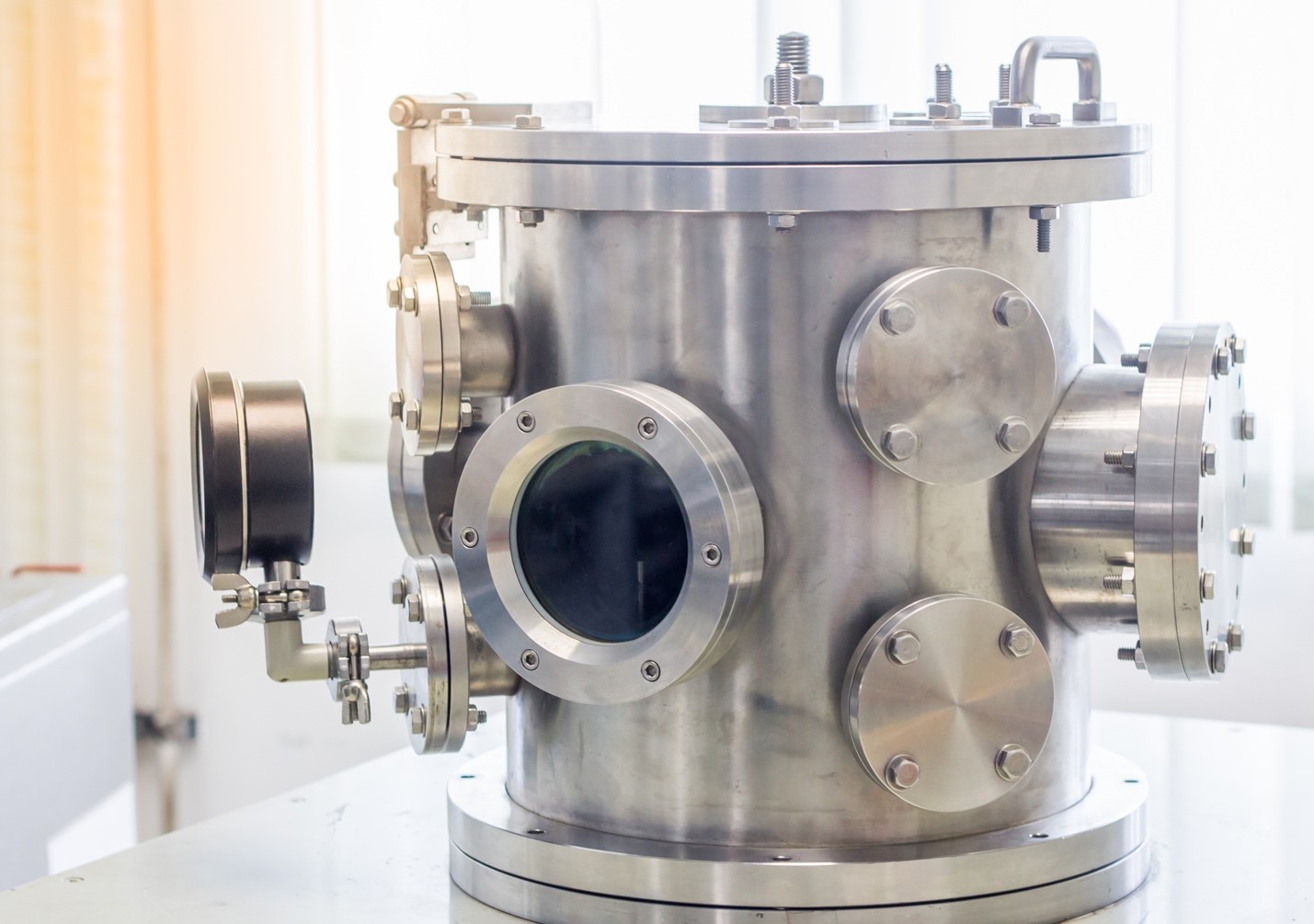

A custom vacuum chamber is a specially designed enclosure used to create a controlled vacuum environment. These chambers are important in a variety of fields of engineering, where it is necessary to maintain specific environmental conditions for various processes.

In this article, we will dive into when you might need a custom vacuum chamber and how they can be implemented.

Using a custom vacuum chamber in scientific research

In scientific research, precision is key. Researchers must create an environment that is free from any external factors that could corrupt their findings. One of the most vital factors to consider with vacuum technology is contamination from the surrounding environment, in particular air and moisture. This is where custom vacuum chambers come in.

Researchers working with materials and equipment that require a controlled environment to maintain integrity typically make use of custom vacuum chambers. These critical pieces of equipment can create an environment that is free of any detrimental contaminants, ensuring a successful outcome for their research.

Vacuum chambers work by removing air and moisture from the surrounding environment, thereby evacuating any unwanted contaminants. Air, as a primary contaminating agent, has many constituents, including atmospheric air, oils and vapors from equipment, and even the air we exhale. Moisture also is another major contaminating agent as water vapor can corrode equipment, promote microbial growth and disrupt delicate experiments.

By using a custom fabrication vacuum chamber, researchers can control the level and pressure of the vacuum in the chamber, eliminating the risk of contamination to the equipment and materials being studied. A custom vacuum chamber also can be designed specifically to accommodate the shape and size of the equipment, making it easier to conduct the experiments being studied.

Implementing custom vacuum chambers in industrial processing

The industrial sector has long relied on vacuum chambers for a variety of applications. One of the most crucial applications is in the semiconductor manufacturing industry. In semiconductor manufacturing, vacuum chambers are used to create specific, controlled conditions necessary to manufacture parts for various processes. These processes require a high degree of precision and accuracy, making custom vacuum chambers an essential component of the manufacturing process.

Vacuum chambers play a critical role in semiconductor manufacturing by allowing certain chemical and physical reactions to occur without interference from external factors. The chambers function by creating a vacuum environment that is free of contaminants like air and moisture, making it possible to produce high-quality semiconductor components.

The specific requirements of each process in semiconductor manufacturing necessitate custom vacuum chambers to perform the necessary operations. A custom-designed vacuum chamber can provide a precise environment that can accommodate the specific needs of a process. For instance, some processes require elevated temperatures, while others require specific pressure conditions, which cannot be achieved through a standard vacuum chamber.

Custom-designed vacuum chambers play an essential role in the manufacturing process as they allow for the exact conditions required for the process to occur.

In space simulation

One of the risks of sending equipment and materials to space is the range of potential damage that can occur due to exposure to the unique conditions in space. Aerospace engineers have grappled with how to manage this issue and have found that custom vacuum chambers are proving to be an essential tool for carrying out their work.

Custom vacuum chambers are a particularly useful tool for aerospace engineers who focus on testing the effects of space conditions on equipment and materials. These chambers are specially designed to replicate the environmental conditions of space, including airless environments and extreme temperatures, among other conditions. By using a custom vacuum chamber, engineers can simulate space conditions on Earth, making it safer and cheaper rather than testing those factors in real-time in space.

Airless environments, for instance, is a key component of space simulations. Items can behave differently in air than in outer space. The dielectric properties are different, and many items change shape or properties with the lack of air. By simulating these conditions using a custom vacuum chamber, aerospace engineers can examine the impact of an airless environment on various components and how airlessness is affecting their properties.

Material processing

In the world of material processing, vacuum chambers are an essential tool for various applications such as coating, drying and degassing. One of the significant benefits of using vacuum chambers is the accuracy, as they take into account factors such as temperature, pressure and atmosphere to provide a precise environment that ensures materials are processed to perfection.

Customized vacuum chambers are essential in material processing and fabrication as they enable companies to select a chamber that meets their specific needs. For instance, some materials may require different pressure or temperature conditions, and a custom vacuum chamber can provide precisely that. Similarly, the size and shape of materials may vary, and custom chambers can be designed and built to accommodate them efficiently.

One important application of vacuum chambers in material processing is coating. Coating is a process where a material, usually in a plasma or gaseous form, is applied to the material being processed. This can be done through a process known as vapor deposition, where the coating material is evaporated and left to settle on the material being coated. Often in these processes, the materials are heated, and the vacuum chamber can ensure that the coating material is applied evenly, and excess material is removed quickly.

Where can I buy a custom vacuum chamber?

GNB Corporation is a great option to buy a custom vacuum chamber. GNB is a leading manufacturer of custom fabrication vacuum chambers, aluminum chambers, ultra high vacuum and more. With decades of experience creating specialized vacuum chambers, GNB offers unparalleled expertise and high-quality craftsmanship to ensure that each vacuum chamber is optimized for its intended use.

GNB provides extensive customization options that allow you to design the perfect vacuum chamber for your specific application. These custom features include explicit size or shape requirements, material compatibility, optimal temperature and pressure rating, port and feed-through positioning and more.

We have the highest of standards and take great pride in our helium leak testing.

Additionally, GNB has an in-house team of mechanical and electrical engineers, as well as a state-of-the-art 3D modeling software that simplifies the design process, so you can receive a custom vacuum chamber that works perfectly for your needs faster.

Contact us today to get started on your custom project.