Why struggle to force an off-the-shelf vacuum component to work when you can have it quickly modified to meet your needs?

At GNB Corp, we believe our customers deserve high-quality products that are promptly delivered, properly priced and convenient. This includes delivering precise customization, if it is needed.

As part of this effort, we have launched a Rapid Vacuum Component Modification Program. Under this program, GNB Corp is able to make modifications to a vacuum component and ship it within 24 hours of getting the order.

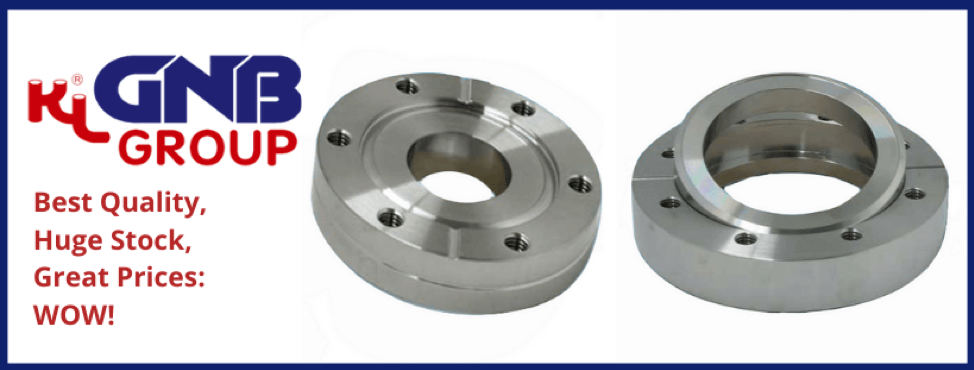

Here is how it works: If a customer orders a standard vacuum item that GNB has in stock and they need a minor modification (customization) of it that can be accomplished in two hours or less of machining time, then we will ship the item within one business day of the time we get the order.

Say, for example, you need to open up of the bore of a flange, drill an extra set of holes, or machine in a hole for a feed-through; we can get that taken care of, quickly. You could have it in your hands the following day!

The Rapid Vacuum Component Modification Program is made possible by GNB Corp’s large-scale production, precision, expansive inventory and experience in modifying parts to meet our customers’ precise specificity.

While there may be a work-around to make a competitor’s component work, there are outside factors that may make it less than optimal. Our goal is to provide a product that’s ready for immediate implementation, allowing you to forge ahead, quickly. When products are less then optimal, companies are more likely to incur unnecessary expenses during the build and installation of equipment.

We don’t want that to ever happen with you.

Perhaps a more complicated custom item is required. At GNB that is no problem, but it will take a little longer than 24 hours. Our large floor space facilitates mass and precise production and immediate delivery. We have large machining centers that can cut up to a 170-diameter-inch part, as well as vertical milling/turning machining centers that have a 10,000-RPM spindle that can handle turning and milling in the same set-up. Additionally, we have a horizontal milling center that has a 10,000-RPM spindle and powerful 3D-compatible software.

Our team will work alongside yours to get answers to questions that will lead to better design, performance and outcome.

This is all part of our winning formula in the vacuum hardware and semiconductor components industry that begins with our desire to exceed customer expectation. We call it the “Wow-Factor” at every step.

In the end, we create excellent products that exceed expectations. GNB Corp caters to customers who believe they can have it all, and who want to be “wowed” with products that perform well and meet their specificity.

Interested in taking advantage of Rapid Vacuum Component Modification Program? Send us a direct message, or visit our website.